Our Products

West

Advantage Outfitters, LLC

255 West Street South

Hackensack

NJ 07606

East

Advantage Outfitters, LLC

Long Island | 107 E. Hawthorne Ave.

Valley Stream, NY 11580

Upfitting your van is an excellent way to improve efficiency, organization and safety. You can install a range of products to upfit your vans, such as shelving, storage accessories, partitions, flooring and roofing equipment. You can even customize your upfit to achieve the best results.

There are many benefits of upfitting your work van. Developing an upfitting plan ensures the process goes smoothly, reducing your downtime and allowing you to make the most out of your van without falling into any common upfitting mistakes. Learn how to upfit a van in this guide.

Upfitting refers to making modifications to a vehicle and customizing it so it fulfills a specific purpose. A van upfitter offers different equipment and accessories to help you modify your van, such as shelving, flooring and organizers.

Many tradespeople upfit their vans to help improve their organization, efficiency and safety. Upfitting can help create more space for your tools, make it easier to access equipment on the job and create a comfortable and safe space for workers.

Multiple industries and trades benefit from upfitting their vans, including:

A van upfit aims to improve your bottom line while you take care of your workers and the community you serve.

All of these industries also have numerous van models to choose from, which will make a significant difference once they start looking for upfitting equipment. Some vans you can choose from or might already own include:

The type of vans your business owns or plans to buy will determine what type of upfitting equipment you purchase. You want to ensure your upfitting equipment is custom-fit for your van’s make and model, allowing you to utilize all of your space efficiently for your specific trade. You don’t want to buy a shelving unit meant for a Ford Transit only to find that it’s too large for your Mercedes Metris, especially since their cargo space capacity is different. Always look for types of vehicle upfitting equipment that are custom-fit to your specific van model.

When you’re upfitting your vehicle, you have many options. The different ways you can upfit a van include:

Choose any combination of upfitting equipment to make the most of your trade or work van. A van upfitter can help you find the right equipment and accessories to improve your efficiency, safety and storage.

There are many advantages of installing upfitting equipment in your work or trade van, such as:

Upfitting your van takes your work to the next level, allowing your workers to complete their jobs efficiently and safely. You can improve turnaround times and increase revenue, helping you excel as a business.

Modify your cargo van by following the steps below:

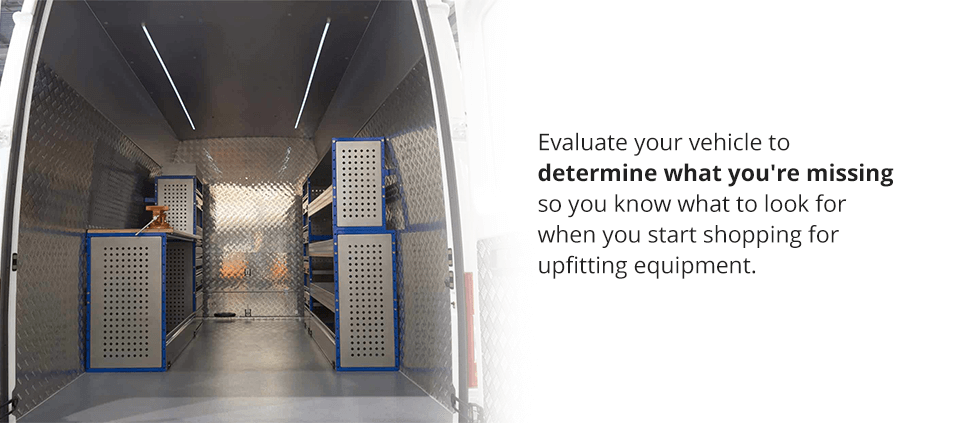

The first step is determining what your vehicle needs. You may have a lot of loose equipment that takes too long to access while you’re on the job. Your cargo and cabin areas may mesh together, leaving your workers vulnerable to loose equipment and tools in the event of a hard stop or accident. Evaluate your vehicle to determine what you’re missing so you know what to look for when you start shopping for upfitting equipment.

Now that you know what you’re missing, create a list of items to help you solve those problems. If you have loose equipment or tools lying around in your cargo area, you could benefit from shelving units and storage containers. You can install a partition or divider if there’s no separation between your cargo and cabin areas. If you’re unsure of the best solution, you could always talk to a professional upfitter for guidance.

Consider your industry and your day-to-day operations here. If you’re in the carrier or delivery industry, consider deep fold-away shelves that can hold hundreds of pounds and bulky items. If you’re in electric or plumbing and have various fittings and fasteners to keep track of, storage drawers can keep you organized.

Once you have your list of what you need, it’s time to shop for upfitting equipment and accessories. You can shop with a trusted upfitter online, get it from a dealer or go to a showroom near you. Browse by your vehicle’s make and model to get the right components for your van.

Once you receive your products, you can install them. Upfitters like Advantage Outfitters offer products that are easy to install, reducing your downtime so you can continue to make revenue. Once your upfitting equipment and accessories are installed, you can continue to do the vital work that benefits your community and business.

Advantage Outfitter’s customer-centric vision allows us to help you choose a van shelving solution that’s best for your industry and commercial vehicle model. Start the conversation with us today on how we can be your partner in upfitting your Ford Transit.

You want your van upfit to go smoothly, ensuring you choose the right parts for the job and reduce downtime. Some mistakes in commercial upfitting could compromise your efficiency and productivity — be aware of them so you can avoid them when you start your upfitting journey. Some common mistakes include the following:

Now that you know the process of upfitting your van and the mistakes to avoid, you’re ready to start looking for customized upfitting equipment to bring your business to the next level. Your upfit can help you get your company closer to peak efficiency, allowing you to complete jobs faster while generating more revenue.

As long as you have a strategy in place and keep in mind the above pitfalls, your upfitting venture can become a success. You can even speak with a professional upfitter at Advantage Outfitters if you have any questions or need some guidance on the best upfitting equipment for your specific van model. They can also help you create a proactive plan to upfit your vans as quickly as possible while boosting productivity and reducing downtime and lost revenue.

Advantage Outfitters is here to help you with all of your upfitting needs. We offer numerous products, including shelving units, partitions, dividers, liners, flooring, roof equipment and accessories. We are a one-stop commercial van outfitter located in New York and New Jersey, and we can help you find upfitting solutions at one of our showrooms. Contact us today to arrange a visit!

You can also shop our products online, where we make shopping simple by arranging all of our upfits by vehicle. Simply choose the model of your van and browse the list or products that fit your vehicle. Our staff can provide you with technical assistance and help you find whatever you need or answer any questions you may have. We can also ship within 48 hours, helping you reduce your downtime and get back on the road. Try Advantage Outfitters today to see why we’re leaders in the upfitting industry!

STAY IN TOUCH

Get access to our tips, deals, project updates, product insights and behind the scenes with our emails.

Advantage Outfitters, LLC

255 West Street South

Hackensack

NJ 07606

Advantage Outfitters, LLC

Long Island | 107 E. Hawthorne Ave.

Valley Stream, NY 11580